Nanotechnology is a rapidly developing scientific discipline with an ever-growing range of critical sub-fields. Thin-film engineering, microelectromechanical systems (MEMS), state-of-the-art therapeutics, and so much more, are built on research and development (R&D) at the nanoscale. Novel materials are central to so many of these breakthroughs; specifically nanoparticles. Colloidal nanoparticles serve an array of functions, and as synthesis techniques continue enhancing, the choice of underlying materials seems near limitless. But research applications often require metallic nanoparticles, specifically silver and gold.

What are silver and gold nanoparticles?

Nanoparticles generally measure between 1 and 100 nanometers (nm). Any more and the material enter the macro-scale while any less approaches the atomic scale. Nanoscale materials, particularly conductive metals, offer myriad beneficial size-dependent properties.

Gold nanoparticles (AuNPs) are versatile and stable objects that are frequently made in a range of sizes, shapes and structures. The shape and size of the nanoparticles play a vital role in the application they are used in.

Silver nanoparticles (AgNPs) are frequently used in biomedical applications, especially in cancer diagnosis. However, they are also used in food, health care, and industrial sectors.

Silver and Gold Nanoparticle Synthesis Techniques: Deposition

Nanoparticles are typically synthesized via bottom-up chemical methods, also known as “wet” chemistry. Solvents are used to nucleate clusters of starter materials into nanoscale structures. Such techniques include precipitation, hydrothermal synthesis, sol-gel synthesis, and electrodeposition. However, these methods often involve several complex and time consuming steps and naturally require the use of potentially hazardous and environmentally unfriendly materials. Additionally, chemical synthesis can be an unreliable process: it is difficult to tightly control key properties, leading to poor reproducibility and a lack of uniformity in composition and size.

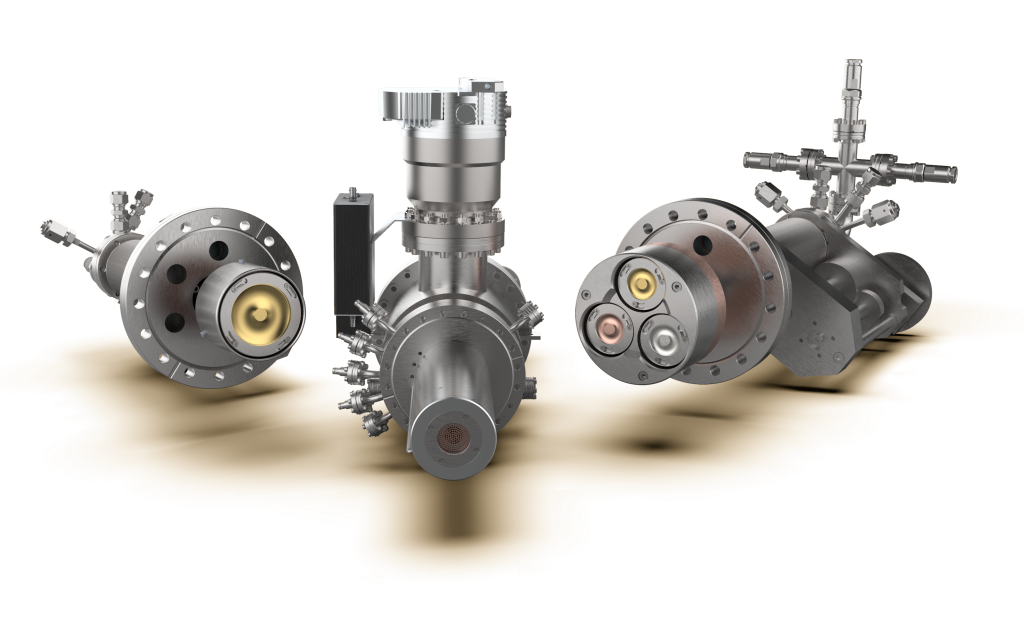

At Nikalyte, we have developed a vacuum nanoparticle deposition technique that ensures the nanoparticles are uniform, hydrocarbon free, and ultra-pure.

Vacuum nanoparticle deposition is a convenient method of depositing ultra-pure and non-agglomerated nanoparticles onto substrates in short timeframes. We deploy magnetron sputtering to generate metallic vapor followed by terminated gas condensation to form a beam of nanoparticles under vacuum conditions with extremely fine deposition control. The surfaces could be rough or uneven and substrates can include plastic, paper, glass, silicon wafer and more.

What Are The Advantages of Deposition?

The deposition method of synthesizing gold nanoparticles has a number of advantages over traditional chemical methods. These include:

Consistent results

The nanoparticles we create through the vacuum deposition technique have enhanced sensitivity used for the detection of ppm and ppb levels.

Ultra-pure

Our deposition process ensures nanoparticles are both hydrocarbon and ligand free.

Safer materials

During the deposition process, no toxic or hazardous materials are used which therefore makes it safer to carry out.

Versatile

You can control the density and thickness of the layers and add the nanoparticles onto any substrate.

Interested in Nanoparticle Deposition?

At Nikalyte, we believe that nanoparticle synthesis should be convenient and hassle-free. That is why we developed the NL50 system, a novel deposition tool suited to industry professionals across the full gamut of nanotechnology applications. Refer to our article on benchtop nanoparticle deposition systems for more information, or contact us today with any questions.