Sputter coating and many other deposition techniques, including PVD, have become essential tools in the research scientist’s arsenal. Modern sputter deposition systems are practically unrecognisable from their earliest counterparts, with vacuum chambers and sputtering systems now operable on the benchtop. There is often a concern that championing ease-of-usability and compactness will lead to compromises on flexibility and quality. But many benchtop deposition systems are versatile enough for compatibility with a range of target materials and substrate types.

This blog post will look at what substrates can be coated with deposition systems and the benefit this provides to research laboratories.

What Substrates can be Coated?

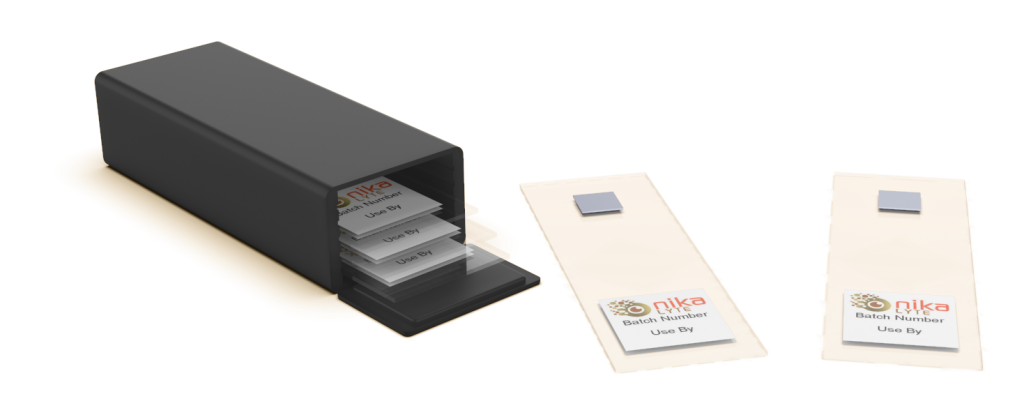

There are a wide variety of substances that can be coated by using a thin film deposition system. However, for this section, we will concentrate on Nikalyte’s NL50 deposition system. Substrates up to 50mm in diameter and of several types are suitable for the NL50, and the system is even suitable for delicate substrates because no heat is generated in the sample chamber throughout the process.

Suitable substrates include, but are not limited to, the following:

- Electrodes

- Petri Dishes

- Plastics

- Membranes

- Micro-well Plates

- Microscope Slides

The deposition method is used to attach nanoparticles onto solid surfaces to create a coating. These coatings help to enhance certain properties of the substrate such as chemical, optical and thermal properties.

In addition to improving substrate properties, deposition coating is also used to protect a substrate. Coatings protect against contaminants, corrosion, and environmental factors but also help to keep a substrate clean, durable and electrically insulated.

Deposition systems are typically used to improve specific components in several applications, some of which include:

Catalysis

By using deposition systems, scientists can improve electrochemistry, fuel cells, photocatalysis, and air and water purification applications. Substrates typically coated for catalysis are those which are metallic and are done so to enhance catalytic performance.

Graphene

The deposition process can enhance graphene applications such as composites, electronics, energy, and sensors. Substrates that are often coated for graphene applications include copper, glass, silicon wafers and others due to their resistance to corrosion, fire, friction and moisture.

Life Sciences and Nanomedicine

Deposited coatings can support applications in the life sciences, including antimicrobial and antiviral biofilms, cancer therapies, and drug delivery applications. These are coated to enhance optical properties, which makes cells easier to observe during biological research.

Photonics

Photonic applications such as light harvesting, photovoltaics and surface-enhanced Raman all benefit from deposition. Substrates coated for photonic applications include glass, metals and photonic crystals, which then increase their reflective properties.

Sensors

Deposition is used in manufacturing biosensors, electrical, electrochemical and optical sensors because the coated substrates, such as electrons, then provide enhanced optical properties.

However, this list is not exhaustive, and other applications can make the most of deposition systems and their processes.

Deposition Systems with Nikalyte

The Nikalyte NL50 benchtop deposition system is the ideal solution for any laboratory. It is compact in design and can be operated by a simple touch screen. By using the NL50, ultra-pure nanoparticles can be created through the vacuum deposition process without hydrocarbons or other contaminants. The process has a cycle time of 30 minutes and does not require any additional drying or purification.

If you would like more information on the NL50 or what substrates can be coated via deposition systems, please don’t hesitate to contact us.