With nearly 20 years of experience, Nikalyte has been at the forefront of solving our customers’ toughest challenges in nanoparticle deposition, thin film coating, and custom vacuum systems. We offer a wide range of solutions, from fully automated, recipe-driven benchtop systems to stand-alone PVD coaters for R&D, and even large-scale reel-to-reel coating systems for industrial applications. Our cutting-edge technology ensures the creation of ultra-pure, non-agglomerated coatings.

PVD Systems

• Thin Film and Nanoparticle Deposition

• Powder Coaters

• HV and UHV

• Custom Designs

• Market Leading Service and Support

Instruments

• Sources: Nanoparticle, Sputter, E-beam, Thermal Boat, Gas Cracker, Atom Source and Hybrid MBE

• Substrate Tables

• UHV Compatible

SERS

• Ultra-Sensitive Detection Down to PPB

• Low Noise

• Reliable, Repeatable Performance

• Competitive Pricing

• Silver and Gold SERS Available

Systems in Action

Trusted by 100+ World-Leading Brands and Organisations, across Academia and Industry

Trusted by 100+ World-Leading Brands and Organisations, across Academia and Industry

News & Events

Latest Blogs

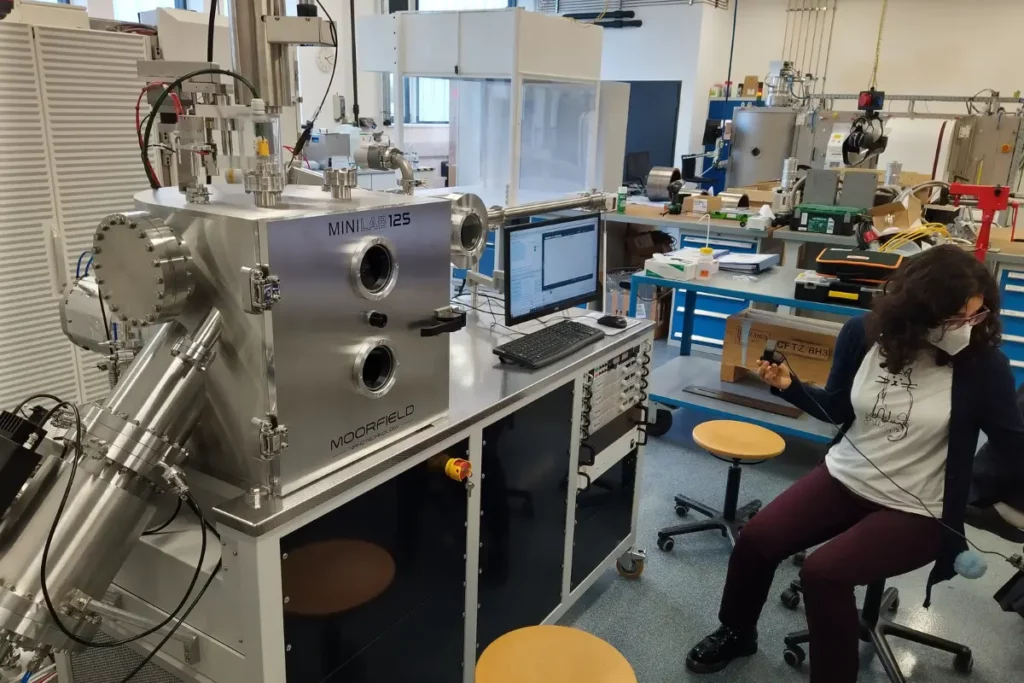

Compact PVD systems

- Low cost, compact, flexible PVD system

- Cycle time under 45 minutes

- Models: 375 (5 sources, 4″ subs) , 300 (4 sources, 2″ subs)

- Front-loading chamber with CF ports, for up to 5 sources

- Upward or downward facing source configuration

- Integrated electronics, pumps, with automation software

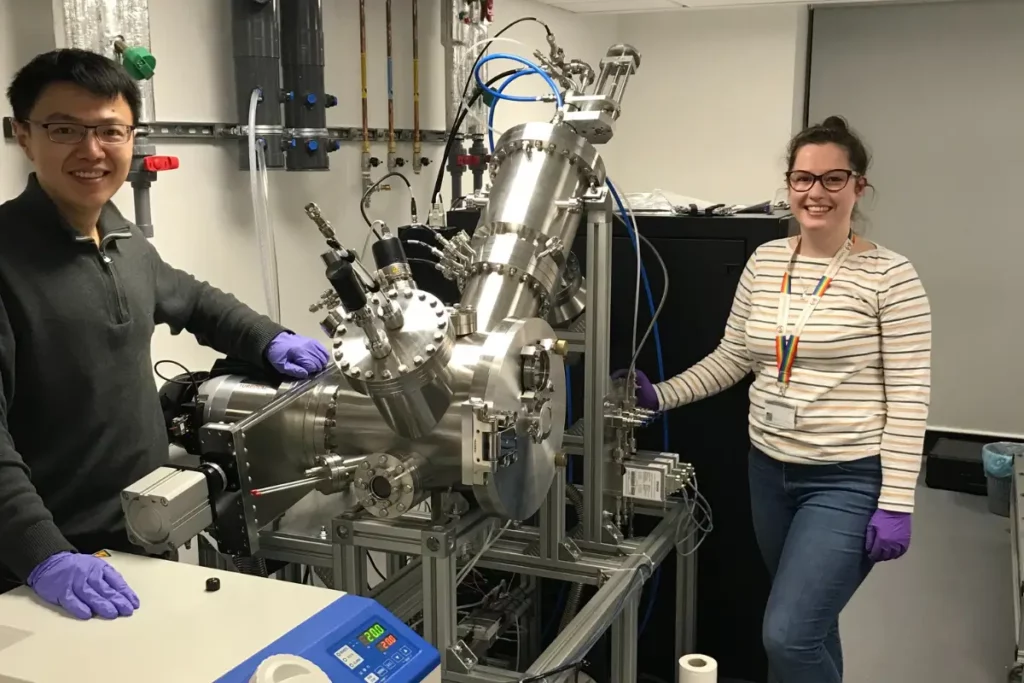

UHV PVD systems

- UHV PVD system with load-lock and bakeout option

- Compatible with Nikalyte and third-party sources

- Confocal CF ports for up to 5 sources

- Substrate stage with rotation, heating, RF/DC biasing

- Fully automated, recipe-driven software

- Create high-purity nanoparticle–thin film composites

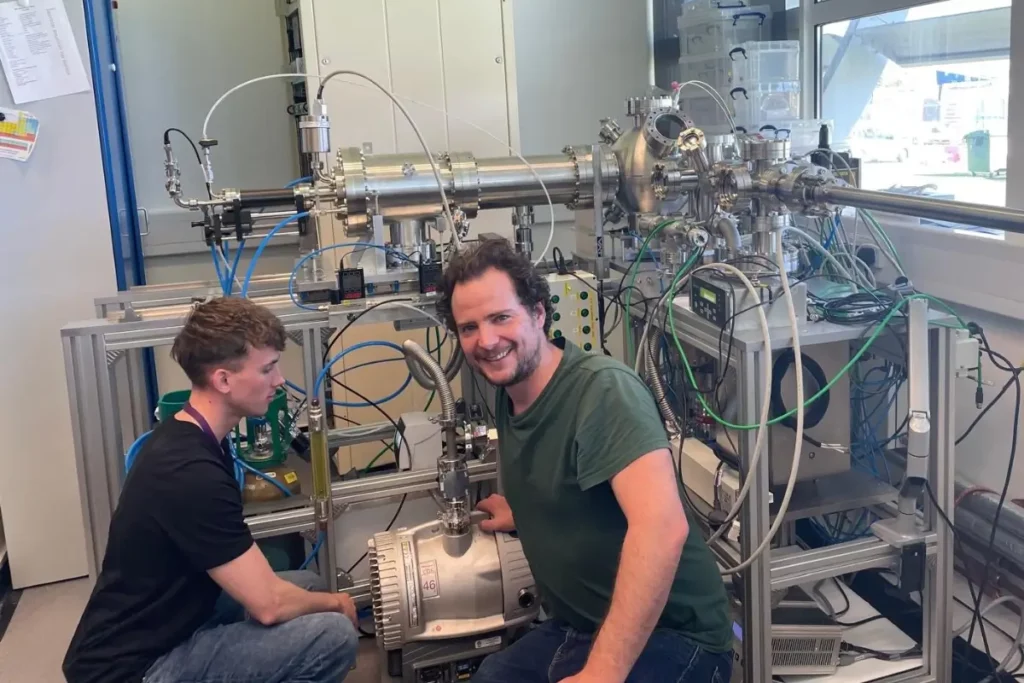

Modular PVD systems

- Front-loading, spacious chamber for easy access

- Upward or downward facing source configuration

- Sample stage with rotation, heating, and RF/DC biasing

- Supports flexible substrates, powder coating, reel-to-reel

- Fully automated, recipe-driven software

- Compatible with third-party sources

Benchtop Nanoparticle system

- Generate metallic/compound nanoparticles (oxides, nitrides)

- Deposit hydrocarbon-free, non-agglomerated nanoparticles

- Wide material selection: Au, Ni, Ir, Pt, and more

- Real-time deposition control via QCM

- Typical cycle time: 30 minutes

- Room temperature deposition for delicate substrates

Powder Coating System

- Compact chamber with vibratory bowl for coating powders and pellets

- Capacity options with bowls up to 2L

- Uniform and repeatable coatings

- Precise control over mass loading

- Inorganic thin film and nanoparticle coatings

- Chemical-free coating with minimal residue

- Automation with PC integration and SPECTRUM software

PVD Systems

• Thin Film and Nanoparticle Deposition

• Powder Coaters

• HV and UHV

• Custom Designs

• Market Leading Service and Support

Instruments

• Sources: Nanoparticle, Sputter, E-beam, Thermal Boat, Gas Cracker, Atom Source and Hybrid MBE

• Substrate Tables

• UHV Compatible

SERS

• Ultra-Sensitive Detection Down to PPB

• Low Noise

• Reliable, Repeatable Performance

• Competitive Pricing

• Silver and Gold SERS Available

Agents and Distributors

EUROPE

AlbaSci b.v.

Cluynshofstraat 33

6227 XS Maastricht

Tel: +31 681 083806

SPAIN

Avactec.

Av. Isabel de Farnesio

34/ Local 13

28660 Boadilla de Monte,

Madrid, Spain.

Tel: +34 910 114 478

Fax: +34 916 321 929

CANADA

Spectral Research Corporation

3585 Laird Rd

Unit 15&16

Mississauga, Ontario

L5L 5z8, Canada

Tel: +1 905-890-0555

Tol Free: +1 886-753-4433

DACH (Germany, Austria and Switzerland)

Dr Martin Oertel

Ziegelhüttenweg 30a

65232 Taunusstein

Germany

Tel : +49 6128 799 33 36

Mob : +49 1573 114 69 31

SINGAPORE

Polaris Science Pte Ltd

18 Kaki Bukit Road 3

#4-10

Singapore 415978

Tel : +65 9671 8388

PVD Systems

Nikalyte designs and manufactures deposition systems for nanoparticles and thin films, utilizing evaporation, sputtering, and plasma technologies.

Instruments

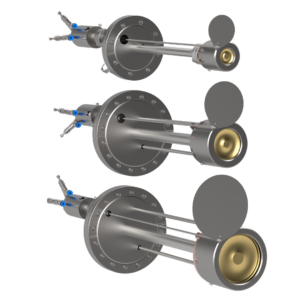

Nikalyte offers a wide range of UHV-compatible PVD instruments, including nanoparticle sources, magnetron sputtering sources, mini e-beam evaporators, substrate tables, baffle valves, thermal boat sources, and thermal gas crackers.

SERS

Nikalytė’s nanoparticle SERS substrates, designed for ultra-sensitive detection down to parts-per-billion (ppb) levels. Available in both Silver and Gold options, our substrates deliver exceptional performance for your analytical needs.

PVD Systems

Nikalyte designs and manufactures deposition systems for nanoparticles and thin films, utilizing evaporation, sputtering, and plasma technologies.

Instruments

Nikalyte offers a wide range of UHV-compatible PVD instruments, including nanoparticle sources, magnetron sputtering sources, mini e-beam evaporators, substrate tables, baffle valves, thermal boat sources, and thermal gas crackers.

SERS

Nikalytė’s nanoparticle SERS substrates, designed for ultra-sensitive detection down to parts-per-billion (ppb) levels. Available in both Silver and Gold options, our substrates deliver exceptional performance for your analytical needs.

PVD Systems

We design and manufacture advanced deposition systems for nanoparticles and thin films, utilizing e-beam and thermal evaporation, sputtering, and plasma technologies to deliver solutions for a variety of applications.

Instruments

We offer a wide range of UHV-compatible PVD instruments, including nanoparticle sources, magnetron sputtering sources, mini e-beam evaporators, substrate tables, baffle valves, thermal boat sources, and thermal gas crackers.

SERS

Our nanoparticle SERS substrates are designed for ultra-sensitive detection down to parts-per-billion (ppb) levels. Available in both Silver and Gold options, our substrates deliver exceptional performance for your analytical needs.

PVD Systems

We design and manufacture advanced deposition systems for nanoparticles and thin films, using e-beam, thermal evaporation, sputtering, and plasma technologies for applications in catalysis, energy storage, photonics, and life science.

Instruments

We offer a wide range of UHV-compatible PVD instruments, including nanoparticle sources, magnetron sputtering sources, mini e-beam evaporators, substrate tables, baffle valves, thermal boat sources, and thermal gas crackers.

SERS

Our nanoparticle SERS substrates are designed for ultra-sensitive detection down to parts-per-billion (ppb) levels. Available in both Silver and Gold options, our substrates deliver exceptional performance for your analytical needs.

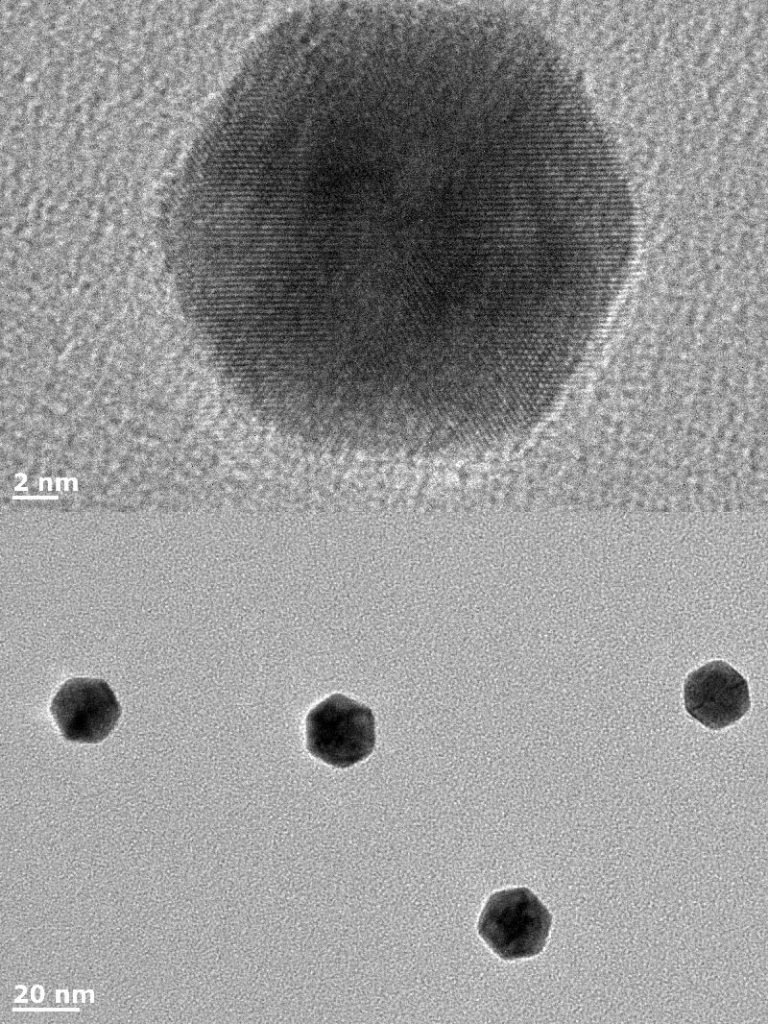

Nanoparticle Deposition

Specialists

Nikalyte have drawn on more than 20 years of experience to bring you the best nanoparticle deposition equipment available. Whether you’re an experienced user or just starting out, we have the equipment you need. Our systems and components operate under vacuum so all the background material impurities are removed, creating ultra-pure, non-agglomerated nanoparticles.

Ultra-pure Nanoparticle Technology

Nikalyte offers a range of nanoparticle deposition equipment to suit your application from benchtop recipe controlled deposition with the NL50 to UHV equipment with complete user control over nano particle size and composition. Alternatively take advantage of Nikalyte’s extensive experience with our bespoke coatings service.

UHV Deposition System

Multi-purpose PVD system with nanoparticle deposition capability at its core.

Modular PVD System

Non-planar & planar, powder coating and reel-to-reel deposition system.

UHV Nanoparticle Source

Deposit pure and alloy nanoparticles with fine control over size and composition.

UHV Sputter Sources

Stellar

High-quality UHV compatible circular magnetron sputter sources.

SERS substrates

Nanoparticle SERS substrates with ppb sensitivity. Choose from silver or gold.

Advantages of nanoparticles deposited in vacuum

Nanoparticles deposited in vacuum are free of hydrocarbons and other contamination which typically plague chemical techniques. Nanoparticles deposited in the NL50 are:

Monodisperse and non-clumping

Ultra-pure and crystalline

Hydrocarbon and ligand-free

Consistent and repeatable results

Deposit nanoparticles as needed directly onto the target substrate

The above properties enables vacuum deposited nanoparticles to boost performance and sensitivity whilst also reducing the required loading of expensive materials for applications such as SERs and catalysis.

How the NL50 Works

How nanoparticles are generated and deposited in the NL50 Benchtop Nanoparticle Deposition System.

What our customers say