Numerous material characteristics can be used to form a catalyst, from nickel and gold to rhodium and copper. Each has properties that can affect the catalyst’s overall activity, stability, and selectivity. One catalyst material that draws attention is platinum. Utilized in catalytic converters and for the creation of hydrogen, platinum catalysts deliver excellent catalytic activity. They also possess great selectivity and have the ability to quicken reactions. Although platinum catalysts are useful, they do have their downsides. The cost of platinum cannot be ignored. Presently, an ounce of platinum is worth about $932.90. Not only is it expensive but there is only so much platinum that exists in the world. Therefore it is unwise to start depending on it. An alternative that could be used in place of platinum catalysts are molybdenum catalysts. Read on to see why molybdenum catalysts could be applied as a replacement.

Defining Molybdenum Catalysts

Molybdenum (Mo) is a metal that is extremely strong and tough. The utility of a molybdenum catalyst stems from its chemical stability, thermal conductivity, and ability to withstand corrosion. These properties mean that molybdenum catalysts can be used in increased heat, conditions which may often be encountered due to their catalytic procedures. They also help the molybdenum catalyst to be extremely robust and employed for longer. The attributes of molybdenum catalysts make them incredibly useful in various areas. For instance, molybdenum-based catalysts can be used to manage pollution, as they can take away heavy metals that are found in air or water, and chemical synthesis. Moreover, molybdenum boride, a molybdenum-based catalyst, can be utilized in the conversion of synthesis gas.

A frequently used method for creating molybdenum catalysts is wetness impregnation, a technique that utilizes wet chemistry. First, a support material is selected, like silica, zeolites, or alumina, before a solution is introduced to it that carries a molybdenum compound. The support material is then infused with the solution. Once completed, the molybdenum catalyst is ready to be activated either through applying hydrogen or an inert gas.

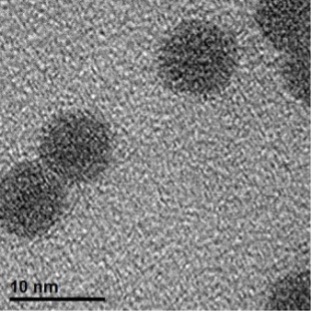

Plasma vapour deposition is another method that can produce molybdenum catalysts. We, Nikalyte, utilize this method for fabricating molybdenum nanoparticle catalysts and can form pure molybdenum, molybdenum oxides, and molybdenum carbides. Essentially, plasma vapour deposition uses plasma to generate ultra pure compound Molybedenum nanoparticles in vacuum which are then deposited directly onto a substrate. Plasma vapour deposition is an excellent technique for creating molybdenum catalysts that offer certain attributes, like increased surface area, great stoichiometry, and precise control over catalyst loading.

The Benefits of Utilizing Molybdenum Catalysts Over Platinum Catalysts

1. Cost

Platinum is an extremely expensive material to use for making a catalyst. Its price is due to the fact that there is not a lot of it readily available. As a result of its expensive nature, there has been a knock-on effect on the use of fuel cells. One suggested methanol-based hydrogen fuel cell system estimated the price of its platinum catalyst would be around $320¹. Instead of using an expensive material, like platinum, it is wiser to utilize molybdenum. This material costs less than platinum. Therefore, molybdenum catalysts are more suitable for large-scale ventures. In addition to this, there are not limited amounts of molybdenum, unlike platinum. Thus, the supply for crafting molybdenum catalysts will be a lot more reliable.

2. Activity

Usually, platinum catalysts make an excellent choice for use in a hydrogen evolution reaction (HER) or oxygen reduction reaction (ORR). These catalysts are excellent at assisting electrochemical reactions. However, molybdenum-based catalysts also have their strengths if applied to a HER. When used as molybdenum disulfide, a molybdenum-based catalyst, in a HER it can deliver great performance.

3. Sulfur Poisoning

Sulfur compounds can poison catalysts. This can influence their active sites, performance, and productivity. Platinum catalysts do not withstand the effects of sulfur compounds as well as molybdenum catalysts. As molybdenum catalysts can resist the impact of sulfur compounds far better than platinum catalysts can, they can be applied to the procedures used for hydrodesulfurization. By being included in hydrodesulfurization, molybdenum catalysts can be utilized to create a positive effect on the environment.

Should Molybdenum Catalysts Be Used Instead of Platinum Catalysts?

The choice between using molybdenum catalysts or platinum catalysts can be tricky. Ultimately, selecting a material for a catalyst should depend upon what the catalyst will be used for. For instance, when undertaking a water-gas shift reaction, it is better to use a platinum catalyst than a molybdenum catalyst, as the platinum offers extensive activity. However, for hydrodesulfurization, molybdenum catalysts should be selected as they can resist sulfur poisoning more than platinum catalysts. An additional consideration is to use both molybdenum and platinum together in a catalyst to improve their functionality. For instance, a low platinum-loaded molybdenum co-catalyst could be used for HER. This is because its activity is akin to what can be seen by using bulk platinum. Through utilizing the two together, a catalyst can be formed that delivers a robust performance without needing to use a lot of platinum.

We, Nikalyte, know a lot about catalysts, specifically the equipment needed to create them and refine the quality of their performance. Our nanoparticle deposition technology can be used to form catalysts out of platinum, as well as many other materials. Reach out to us, Nikalyte, and we will provide you more information about our devices.

Reference

- Yirka B. Using platinum-molybdenum carbide to catalytically release hydrogen to power a fuel cell. Phys.org. https://phys.org/news/2017-03-platinum-molybdenum-carbide-catalytically-hydrogen-power.html. Published 31st March 2017. Accessed 25th July 2024.