Alloy Nanoparticle UHV Deposition Source: NL-UHV Series

The NL-UHV Series nanoparticle (cluster) sources generate pure and alloy nanoparticles in ultra-high vacuum to create functional coatings. They offer precise control over nanoparticle size, composition, and structure. Size filtering is achieved using an inline mass filter.

NL- UHV Nanoparticle Deposition Source uses the Terminated Gas Condensation Technique, that generates nanoparticles by rapidly cooling and condensing gas-phase metal or alloy vapors into nanoparticles within an ultra-high vacuum (UHV) environment. In this metal vapors is sputtered from the target surface by an argon plasma and then travels through the aggregation zone where it cools to form nanoparticles. This technique allows for precise control over the nanoparticle’s properties, such as size, composition, and structure, making it ideal for producing high-quality functional coatings, and other advanced materials for research and industrial applications.

Available in a single 1″ source (NL-D1), 2″ source (NL-D2), or triple 1″ source (NL-D3). The NL-UHV can be integrated into an existing PVD systems or our custom NL-CUBE and NEXUS system.

Key Features

- Deposit pure and alloy, hydrocarbon-free, non-agglomerated nanoparticles.

- Achieve sub-monolayer or high-porosity 3-D nanocoating.

- The NL-D3 facilitates the deposition of up to three materials, either individually or as alloys, using two or three materials at the same time.

- All sources are compatible with both DC and Pulsed DC power supplies.

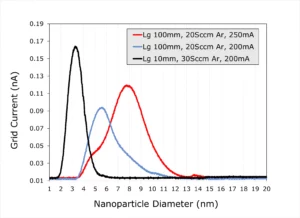

- Control the properties of the nanoparticle coatings by adjusting various process parameters, such as gas flow, gas type, magnetron power, and aggregation length (Lg), or by altering the size of the aggregation zone aperture.

Control of Nanoparticle size using NL- QMS

Quadrupole Mass Spectrometer

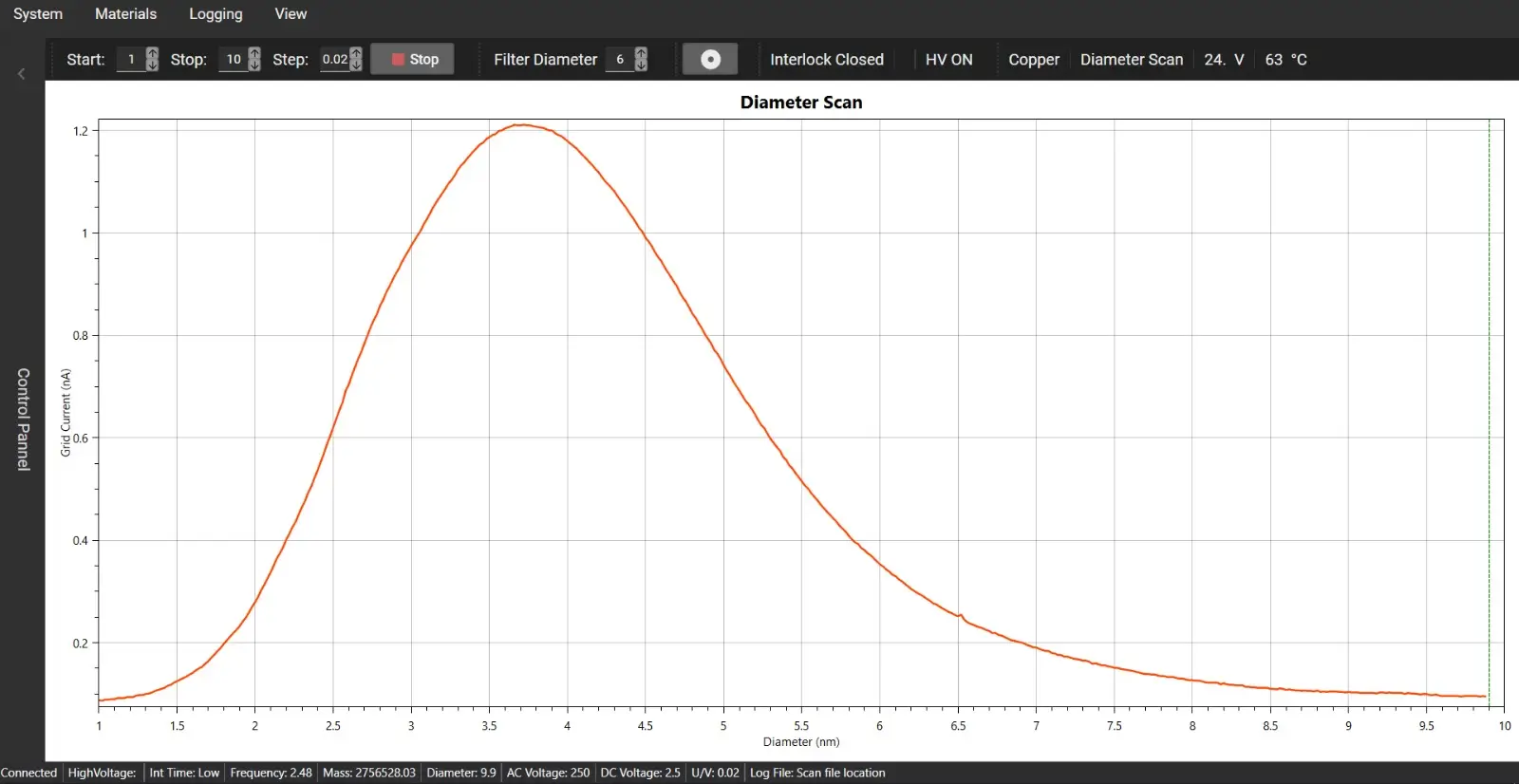

The NL-QMS mass filter enables real-time scanning or filtering of deposited nanoparticles by mass or diameter, facilitating the optimization of growth conditions.

Highlights

⇒ Adjust the nanoparticle size distribution within the range of 1 – 20 nm.

⇒ Modify the nanocoating layer density from a sub-monolayer to 3D nanoporous coverage, facilitating coatings that range from loosely bound to tightly adherent.

⇒ Manage the nanoparticle shape and structure, transitioning from crystalline to amorphous forms.

⇒ Conduct mass spectrum analysis of nanoparticles in flight, covering a range from 100 – 10 6 amu.

⇒ Implement nanoparticle size filtering with a mass resolution accuracy of +/-2%.

NL- QMS Control Software

The NL-QMS is operated through a simple and user-friendly Windows™ software interface.

Highlights

Data logging for mass spectra

Preloaded mass calibration data for standard materials

Input parameters for novel materials or alloys

Complete control over QMS operations and scanning configurations

Specifications

| Utility | NL-DXX | NL-QMS |

| Mounting Flange | DN160CF | DN160CF |

| Power | 630V DC or Pulsed DC | 100-250Vac 4Amp fuse |

| Gas | Argon/Helium 2-100Sccm | |

| Cooling Jacket | Water or LN2 Flow rate 2l/min (0.52 US GPM) | |

| Pumping | 120L/m (4.2 CFM) Backing pump 300L/m (10.6 CFM) Turbo pump | |

| Aperture plates | 2mm, 3mm, 4mm and 5mm aperture plates supplied as standard |

NL-DXX Options

| Source Options | NL-D1 | NL-D2 | NL-D3 |

| Source Output | 75W dc | 100W dc | 3 x 75W dc |

| Sputter Target | 1 x 1″ | 1 x 2″ | 3 x 1″ |

| Target Thickness | 0.5 – 3mm | ||

Publications

Mouti, N., Kostoglou, N., Obenaus-Emler, R., & Mitterer, C. https://doi.org/10.1116/6.0004328

Çiçek, A., Kratzer, M., Teichert, C., & Mitterer, C. https://doi.org/10.3762/bxiv.2025.46.v1

Florian Knabl, Christine Bandl, Thomas Griesser, Christian Mitterer. DOI: 10.1116/6.0003283

Florian Knabl. DOI: 10.34901/mul.pub.2024.129

Elizabeth S. Jones, Dr. Charalampos Drivas, Dr. Joshua S. Gibson, Dr. Jack E. N. Swallow, Dr. Leanne A. H. Jones, Thomas D. J. Bricknell, Dr. Matthijs A. van Spronsen, Prof. Georg Held, Dr. Mark A. Isaacs, Dr. Christopher M. A. Parlett, Prof. Robert S. Weatherup. DOI: 10.1002/cctc.202400239

Florian Knabl, Dominik Gutnik, Prathamesh Patil, Christine Bandl, Tijmen Vermeij, Christian M. Pichler, Barbara Putz, Christian Mitterer. DOI:10.1016/j.vacuum.2024.113724

Edwards, P.J., Khojasteh, M., Halder, A. et al. DOI: 10.1007/s10948-021-06062-y

Cong, P., Gibson, J., Jones, E., Swallow, J., Liu, L., Jones, L., et al. DOI: 10.26434/chemrxiv-2025-0cgp0