Benchtop Nanoparticle Deposition System : NL50

The NL50 is a benchtop vacuum system that deposits ultra-pure, non-agglomerated nanoparticles onto surfaces up to 50mm in diameter. Designed for shared research or teaching labs, it supports various nanotechnology projects without cross-contamination.

The Benchtop Nanoparticle System using the Terminated Gas Condensation Technique is a compact, high-precision tool designed for the controlled deposition of pure and alloy nanoparticles. By rapidly cooling metal or alloy vapors in an ultra-high vacuum environment, this system produces non-agglomerated nanoparticles with precise size and composition control. Ideal for research and development, this system enables the creation of functional coatings and advanced materials for a wide range of applications, including catalysis, energy storage, photonics, and life sciences.

Key Features

- Deposit hydrocarbon free and non-agglomerated nanoparticles

- From sub-monolayer to high porosity 3-D nanocoating

- Surface plasma cleaning and functionalisation

- Generate pure metallic or compound nanoparticles such as oxides and nitrides.

- Wide choice of materials, including Ag, Au, Cu, Ni, Ir, and Pt

- Real time deposition control using a Quartz Crystal Microbalance(QCM)

- Repeatable process with typical cycle time of 30 minutes

- Room temperature deposition is compatible with delicate substrates such as graphene, membranes and plastics

Specifications

| Weight | Approx. 60Kg (113lbs) |

| Dimensions | (LXWXH) 70 x 50 x 60cm (27.6x 19.7 x 23.6 inches) |

Consumables

| Target size | 1inch (25.4mm) diameter, max 3mm thick |

| Max Sample Size | 50mm diameter |

| Materials | Conducting materials, including Ag, Au, Pt, Cu, Ni, Ti, Ir |

Control Software

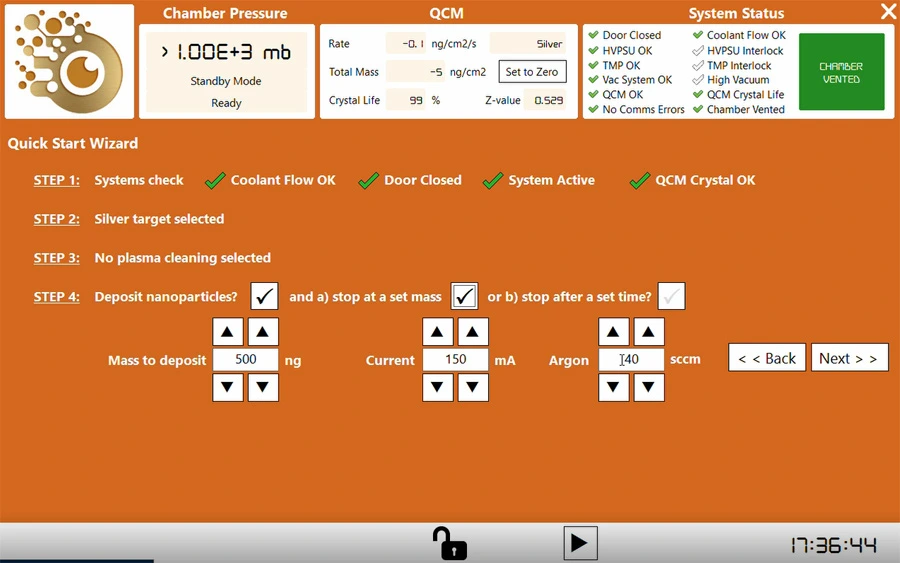

The intuitive user interface is easy to use and does not require any previous vacuum experience. Preloaded deposition recipes enable users to start depositing nanoparticles straight away.

Highlights

- Full automation of the pump down and deposition sequence.

- Preloaded optimised deposition settings for common materials such as Au, Ag and Pt.

- Advanced users have the option to control deposition conditions to manipulate nanoparticle size and deposition rate according to their specific needs.

- Control nanoparticle loading using deposited weight or deposition time.

- Automated logging of all process and vacuum parameter.

NL50 'how-to' videos

5 Videos

1.06

1.08

2.18

1.14

1.01

Publications

S. Aktas, S. Durdu, T. W. Bird, K. Ozcan, G. Yigitturk, S. L. Aktug, M. Usta, T. Acet, and A. Pratt https://doi.org/10.1021/acsomega.5c09046

C. Liu, A. Liu, Z. Zhou and C. Liu. https://doi.org/10.1109/ICSJ55786.2022.10034730

A. M. Lister, Y. Wang, B. I. Armitage, W. Li, and M. R. Castell https://doi.org/10.1088/2515-7639/adb337