Nanoparticle & Thin film UHV Deposition System : NEXUS

Key Features

- Generate complex materials by combining nanoparticles and thin films

- Hydrocarbon free nanoparticles using NL-UHV

- UHV system with load-lock, bakeout and pumping upgrade option

- Combination turbo/dry backing pumping

- Confocal port geometry for up to 5 sources

- Compatible with third party sources

- Coating of substrates with rotation, heating and biasing options

- Interlocks to protect both personnel and equipment

- Fully automated and recipe driven software

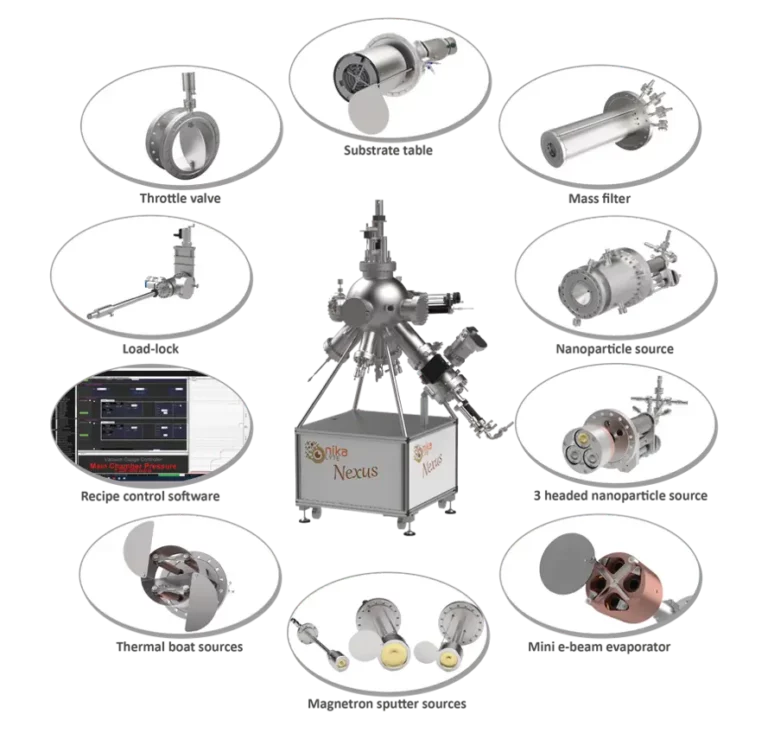

Basic System Configuration

| Size of deposition chamber | 450 mm |

| Base Pressure | < 5e – 7 Torr |

| Orientation | Sputter up |

| Sample table | 4-inch wafer, 20rpm rotation, Z-shift for sample loading/unloading |

| Pumping | 300l/s turbo with 7.2m3/hr dry backing pump |

| Valves | Manual valves, shutters and linear drives |

| Control Software | Recipe driven processes, power supply control and data logging |

| In-situ monitoring | Quartz Crystal Microbalance for process monitoring and end point detection |

| Source Port | Up to 5 deposition sources 2 Confocal CF150 and 3 confocal CF100 source ports |

| Source Type | Nanoparticle source, Magnetron sputter sources, Mini e-beam evaporator, Thermal boat source K-cells, Ion source, RF Atom source |

Options

- 5e – 9 Torr base pressure (With bakeout option)

- Sample stage:-

– DC bias for nanoparticle acceleration

– RF bias for sample surface cleaning

– Heating to 800°C

- Pumping – 700l/s turbo

- Separately pumped load-lock with transfer arm

- System bakeout

- Automation options for valves, shutters and linear drives

- Adjustable baffle in front of turbo to increase dynamic pressure range for sputtering at lower gas flows

NEXUS System Configuration Options

Control Software

The intuitive “drag and drop” user interface is easy to use and allows full automation of the pump down and deposition sequence.

Highlights

⇒ Fully automated pump down and venting

⇒ Configure Virtual Rack to suit your process

⇒ Easy to add and remove instruments

⇒ Real Time Charting

⇒ Interlock Monitoring

⇒ Recipe Control

⇒ Data Logging Functions

Publications using Nanoparticle Technology

Antía Villamayor, Alonso Alba, Laura V. Barrio,Sergio Rojas, Eva Gutierrez-Berasategui. DOI : 10.3390/coatings14070868

A Caillard, S Cuynet, T Lecas, P Andreazza, M Mikikian, A-L Thomann , P Brault. DOI : 10.1088/0022-3727/48/47/475302

Aver Hemben, Iva Chianella , Glenn John Thomas Leighton. DOI : 10.3390/bioengineering8030038