By producing carbon dioxide (CO2) emissions, ultimately totaling 34-36.8 billion tonnes of CO2 every year, the planet is being endangered. About 45% of this CO2 is from fossil fuels, with estimates being made that fossil fuels have been responsible for at least 67% of the Earth’s rise in temperature.

One solution to reduce emissions is carbon capture and storage (CCS). Here captured carbon is placed in a storage site, such as a gas and oil reservoir. Captured and stored carbon aside, another method for dealing with CO2 is available. This is CO2 capture and conversion.

CO2 capture and conversion turns the CO2 into a new product instead of releasing it. CO2 is captured from the flue gas in power plants or gas from industrial processes. Then it is changed into a new chemical, such as ethanol or ethylene. Metal oxide catalysts enhance the CO2 capture and conversion process because of their selectivity and chemical and heat-related stability.

Read on to discover more about how metal oxide catalysts can improve the CO2 capture and conversion process.

Oxygen Vacancies and Surface Defects

One of the pivotal characteristics that make metal oxide catalysts effective for CO2 activation is the presence of rich surface defects or high concentrations of oxygen vacancies. These structural anomalies play a dual role. They not only serve as adsorption sites for CO2, thereby capturing the greenhouse gas, but also enrich electrons.

The enriched electrons can be transferred to the neutral CO2 molecule, effectively activating it for subsequent conversion processes without necessarily transferring electrons directly. This mechanism underlines the efficiency of metal oxide catalysts in facilitating the initial step of CO2 capture and conversion.

Binding and Activation of CO2

The interaction between metal oxide catalysts and CO2 molecules is further elucidated through the binding and activation process. Essentially, the oxygen atom from the metal oxide can bind to a surface metal cation. This results in the weakening and elongation of the C-O bond within the CO2 molecule. Altering the CO2 molecule’s structure is critical for activating it before its conversion into chemicals and fuels. The process highlights the catalytic prowess of metal oxides in capturing CO2 and preparing it for conversion. This is all without the need for direct electron transfer.

Versatile Catalytic Properties

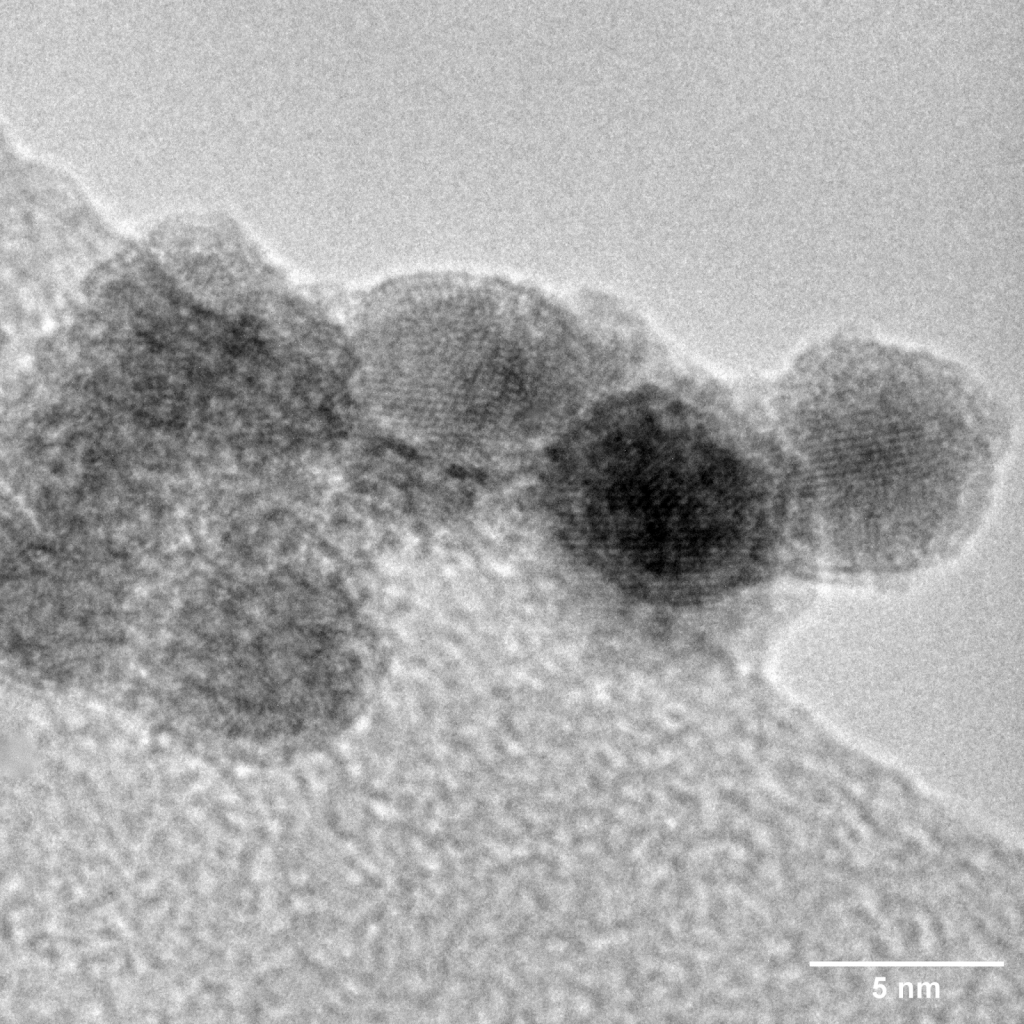

The versatility of metal oxide catalysts is another factor contributing to their suitability for CO2 conversion. These catalysts, ranging from pure metals to metal oxide nanoparticles, exhibit a wide array of catalytic properties including:

- Electron transfer capabilities

- Morphological changes

- Chemical ordering.

Overall, their versatility ensures metal oxide catalysts can be tailored to catalyze a broad spectrum of CO2 conversion reactions. Ultimately, this makes them invaluable in the quest to transform CO2 into useful products.

Dual Functionality

A remarkable feature of metal oxide-based materials is their dual functionality. These “dual function materials” can simultaneously adsorb CO2 and catalyze its conversion into value-added products. Examples of these products include methanol and hydrocarbons. This dual action simplifies the overall process and enhances its efficiency. As a result, a compelling case is made for using metal oxide catalysts in CO2 management strategies.

Stability and Cost-Effectiveness

Beyond their catalytic capabilities, metal oxide catalysts are lauded for their stability, cost-effectiveness, and ease of recovery. These attributes are essential for the practical application of CO2 conversion technologies. This makes metal oxide catalysts a preferred choice for sustainable CO2 management.

Embrace the Future of Catalysis with Nikalyte

As the global community marches towards sustainable solutions for energy conversion and environmental restoration, the pivotal role of advanced materials in catalysis cannot be overstated. With their unique nanoscale properties and structural versatility, metal oxide catalysts stand at the forefront of this scientific revolution. They promise a greener, more efficient world.

At Nikalyte, we are passionate about fueling this transformation. Our cutting-edge nanoparticle deposition systems empower researchers and industries to explore the vast potential of metal oxide nanoparticles. These systems include the Nikalyte NL-UHV.

From the efficient production of multi-carbon products through electrochemical CO2 reduction using copper oxide nanoparticles to pioneering water electrolysis applications with iron-nickel (Fe-Ni) based catalysts, the possibilities are boundless.

The Fe-Ni catalysts are just a glimpse into the future that Nikalyte will help to materialize. These catalysts are highlighted by their:

- High efficiency

- Abundance

- Electron flexibility

- Structural versatility

- Cost-effectiveness.

Through offering ultra-pure metal oxide nanoparticles tailored in size, composition, and structure, we provide the tools for breakthroughs in heterogeneous catalysis and beyond.

As we push the boundaries of what is possible, we invite you to join us on this journey. Explore the transformative potential of metal oxide catalysts with our NL-UHV system. Then you can take the next step towards a sustainable future.

Enhance the CO2 Capture and Conversion Process through Metal Oxide Catalysts

New technologies need to be developed to reduce the CO2 in the atmosphere. From the 1880s, there has been a 1.1°C rise in the temperature of our planet. So, should you want to try and reduce the levels of CO2 building up in the air, you can do so through CO2 capture and conversion and the application of metal oxide catalysts.

Visit our website to learn about our technology in relation to metal oxide catalysts and CO2 capture and conversion processes. We have already mentioned our NL-UHV system. Nikalyte’s technology can also help to create nanoparticle catalysts from copper, platinum, or ruthenium. Contact us for more details now!